Synthetic Stucco

A Little History

Synthetic Stucco is also referred to as EIFS which is short for Exterior Insulated Finish System. The system was first used in Europe after the end of WWII. The product was first installed on commercial buildings in Germany. Builders in the United States brought the technology here in the 1980's. As in Europe, the early installations were on commercial buildings (shopping plazas, offices, etc.). With much success, builders and architects then began experimenting with residential applications. However, the primary difference was in commercial applications and in Europe, the system was installed mostly over concrete, stone, brick or similar dyrable materials. With residential applications, the system was installed over mostly wood frame construction and therein lies the problems.

What Exactly is EIFS?

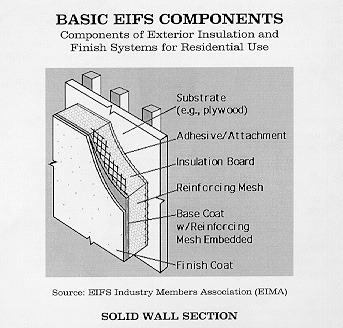

The Exterior Insualted Finish System is made up of three layers:

1) Inner Layer 2'x4' foam insulated board that's secured to the exterior plywood or OSB sheathing, often with adhesion.

2) Middle Layer A polymer and cement base coat that's applied to the top of the insulation, then reinforced with glass fiber mesh.

3) Exterior Layer A textured finish coat. Usually this is an acryllic, rubber based product applied in one or two coats with the final coat being 1/16th to 1/8th inch thick.

The Benefits

Benefits included ease and quickness to apply which in turn meant lower costs to install. The foam board behind the stucco provided additonal insulating benefits. The finish color was consistent throughout the texture, making it in theory low maintenance. Interesting design features and details could be added to the homes look creating lots of curb appeal.

So Why All The Fuss?

EIFS was meant to be a barrier system, meaning it was not intended for water to get behind the finish. Once water got behind the finish, the moisture was trapped, causing wood rot at the wood framing and sheathing of the home, as well as creating mold and mildew. In the eraly 1990's the first reported case of EIFS damage was discovered on homes in Wilmington, NC. Removal of the stucco revealed extensive structural damage due to wood rot.

How Did It Happen?

It was determined the builder and installing stucco companies failed to install proper window, door and kickout flashings, back-wrap at openings, leaving leaking window and door frames. In addition, it was discovered that the foam behind the stucco, when installed at or below grade, was conductive to termite and fire ant infestation. The stucco and foam board at the ground level also created a wicking condition when wet. As problems multiplied, The Exterior Design Institute was formed to educate and train independent third party inspectors and applicators. Various installation protocols were established.

What If I have Synthetic Stucco?

Not all synthetic stucco applications are inferior. If you think you may have moisture problems or wood rot caused from stucco, your exterior stucco surfaces should be thoroughly inspected by a certified stucco inspector. An inspector will perform a visual and non-invasive inspection to determine moisture content and veirfy application methods. Some of the things an inspector will check for are cutbacks at ground level, kickout flashing at roof-lines where gutters terminate against a wall, flashing over doors and windows, expansion joints between 1st and 2nd stories, bevels on decorative trim and sills and most importantly, to check for mushy, cracked or convex stucco surfaces. Tools used to inspect for moisture include a surface moisture meter, probe moisture and even infrared thermography. Any probes through the surface should be caulked with appropriate sealant after the test. The inspector may also look for signs of mold or mildew on the interior walls as well.

How Do I Maintain Synthetic Stucco?

There are five simple steps any homeowner can take to keep your stucco moisture free:

1) Any openings, such as door and window frames and the areas around flashings, must be sealed to prevent water from seeping behind the EIFS.

2) Gutters should be kept clean and downspouts should be positioned to drain away from the house.

3) Foam board and mesh should not be exposed or extend below grade. Typically a 4-6" cutback (gap) is desired from the soil to the bottom of the stucco.

4) Any item that penetrates the stucco must be sealed. For example, any screws or nails (for decorations) should be caulked at the surface.

5) To the extent possible, keep shrubbery and tree limbs from making contact with the stucco. Typically, a 6" clearance is desired. Vegetation may transfer moisture to the stucco surface.

Synthetic or Hardcoat Stucco; What's the Differnce?

Hardcoat stucco has no insulation foam board or fiber mesh. Generally, a scratch coat is applied to the sub-surface and then a wire mesh is installed with multiple layers of finish coat applied over the mesh. To the touch, hardcoat is hard and brittle and sounds solid when tapped. EIFS is soft and sounds hollow when tapped.

Are There Problems With Hardcoat Stucco?

Yes, but no to the degree of synthetic stucco. It still goes back to how the system was installed and were the proper steps taken to seal entry points.

Are Builders Still Using Synthtic Stucco?

Not in residential applications. EIFS is still used in commercial applications on metal or concrete sub-straight walls.